Travel 2020-2021

Faucet and Propane Regulator

Plumbing — water, sewer, propane — is all pretty simple. Until it leaks. Then it’s a right pain in the ass. Leaks can be difficult to diagnose. It’s not always a good idea to tighten things down harder. Sometimes over-tightening breaks something else.

Neither CA nor I grew up with propane. Not a grill. Not a camp in the woods. Nothing. We didn’t even know what the injected smell was supposed to smell like.

Years ago, our propane line — from tank to regulator — failed. And drained the tank. That’s not supposed to happen, but the tank was old and there didn’t seem to be a proper Excess Flow Valve. We had no clue until the cooker didn’t work.

We had a crazy amount of help from a random sailor in St. Mary’s, Georgia.

The solenoid failed a year and some later. I had a boatyard guy replace it.

I’ve been terrified of the propane system. We’ve had a few times when the gas simply would not flow. Generally, it was cold. And maybe turning the gas on too quickly tripped the EFV. Or maybe. The regulator was ancient.

Either way, I didn’t want to touch it.

I bought a new regulator. And then the old one started working again. So. The replacement sat in a drawer.

Last weekend, the old one didn’t work. I got some yellow teflon tape, and replaced the regulator. It was easier than I thought it would be. There are only two fittings, and they turned nicely.

Turn the gas on, note the pressure. Turn the gas off. Come back in three minutes. Same pressure? System is good. Loss of pressure? You have a leak.

The picture sort-of shows the new regulator on the left. One of the tanks on the top. And on the bottom? A gallon iced-tea jug we use for things like oil changes or bilge water. Just a jug. In between the propane cans.

Faucet

The old galley sink faucet dripped. And in the right combination of faucet position and spigot position, it leaked all over the counter-top. CA suggested we get a new core for the mixer. It was a conventional Delta-brand faucet. Easy to do.

Until I stripped out the hex nut holding the handle on. Then it suddenly became impossible to do.

Rather than simply replace the core, we’re going to replace the whole thing.

This is the replacement: a “Classic” 13900LF-SS, It needs a hair over 2 ½″ of space.

On the right, you can see a sprayer. CA insisted. The new-fangled sprayers hanging from the spigots are fun, but, complicated. This is simpler.

This only has two connections. But it leaked.

And leaked.

And leaked.

Here’s me, watching it leak.

I spent — I don’t know — two hours fussing around with one thing.

One thing.

The hot-water connection.

It leaked.

And leaked.

And leaked.

I had to research Qest/Quicktite and Zurn fittings for Polybutyl (PB) pipe. We’re talking a nut wrapped around a grip-ring and a cone. The leak was not from the connection to the faucet via a nice ½” brass fitting. The leak was inside the nut, where it ran down the PB pipe.

The solution?

Trim about ½″ off the end of the PB pipe. Push on the grip-ring and the cone over the new, clean, pipe.

Much nicer.

I realized it would be nicer because I couldn’t move the cone once I pushed it on. It had dropped off the pipe before. But cutting away that last ½″ changed everything.

The nut threaded on easier, too. Not sure why, but I think it was snugging up against the brass fitting more cleanly.

Turn on the pump and apply pressure. (Again. This has to be the 12th time today.)

No Leaks.

So. That’s two good deeds: propane and water.

We can live much more comfortably with working cooking gas and water.

Next: Hawsepipe.

The Built-In Cutting Board

CA likes having countertop she can use directly. A loose cutting board on a moving boat is a liability.

The Whitby has a nice cutting board built in the top of the refrigerator.

This has consequences. Mostly it means having any ingredients that need chopping out of the fridge before you start meal prep. Otherwise, you have to move *everything* because you forgot the cherry tomatoes.

(We don’t use this as a fridge, but the rule still applies: have *everything* ready.)

For the past ten years, CA hasn’t liked the condition of the cutting board. It had a finish that was peeling in places.

Peeling.

It was icky.

We read about using food-grade mineral oil as a treatment for wooden cutting boards. This meant stripping the old surface, which seemed like a job-and-a-half.

Since it was pouring outside. (And cold.) CA decided to sand the old surface and (finally) put on a proper finish.

She started with the sanding block and a random piece of sandpaper. After her shoulder started to hurt, she was ready to talk about power tools.

This can be a big step. Tools are noisy and dangerous. A sanding block is quiet and safe.

I showed her how to put paper into the sander. After a few tentative sweeps (“It’s gouging the wood, and it’s not a perfect finish”), she understood the progress of grits. And then tore into the job. Cackling with glee. Seriously cackling. It’s fun to sand a small, well-made plank that’s firmly attached to the boat. The sander has a dust-bag so there isn’t volumes of sawdust everywhere. There’s immediate joy seeing the changes in the wood.

She used 80-grit, 150-grit, and a final pass with 220-grit to create a super-smooth surface. I was lobbying for running out to get some 400 grit. She was having none of it. Four coats of mineral oil later, she’s got a new place to cook.

(I’m hoping for cinnamon buns.)

Me?

I measured the offset between sink and backsplash. 3″. This tells me which of the Delta faucets I can wedge into the available space. (The answer is “almost anything your little heart desires, as long as it’s stainless.” I think the 13900-LF-SS is the faucet for this job.)

Up next? Replace the propane regulator so we can actually cook again. This is terrifying. Propane. Boom.

Also, the electric spark on the Force 10 isn’t sparking. I’ve replaced the spark module and the push-button. It’s unlikely to be the electrical connection on the knobs (all three failed at once??) It’s slightly more likely to be the spark unit on one of the burners shorting out. I say this because the burners had not been dismantled to be cleaned in years. I had to pry one of them apart because some spilled food had sort of welded it together.

The final potential failure is a nick in the wire somewhere causing a short via the metal frame. This is a right pain to diagnose.

For now, I’ll enjoy the new cutting board.

Leaks and the Wrong Goo

There are two important classes of chemicals. Goos and Lubes. Goo to make things stop. Lubes to make them go.

They each have specialized purposes. It helps if you know what you’re doing. And in some cases, you learn as you go. This is one of those lessons learned.

The chainplates — slabs of steel that anchor the wire rope holding the rigging upright — pass through the deck. When we replaced the chain plates, we had to fill the openings in the deck. With a goo.

But which goo?

Originally, the boat was assembled with a fiber pounded into the slots and a gooey sealant over the top. What was the fiber? Wool? Oakum? The glass fibers used for insulation? The glass fibers for fiberglass? No clue. I only know there was a puff of stuff that came out with each chain plate.

I tried to use goo-in-a-tube to reseal the opening around the new plates. The gaps were too huge. They all leaked like crazy.

Someone told me Butyl Tape is the preferred goo for this job. Stretchy. Tenacious. Essentially indestructible except by UV exposure.

Closely related is “putty tape”. It’s not as stretchy.

It appears, I bought the cheaper "putty tape."

CA ordered proper butyl tape. It’s super-stretchy. Super-flexible.

Since the weather’s warm, and winter’s coming on, she’s redoing all the feet of all the chainplates with the new, fancy butyl tape. This will, we hope, reduce water intrusion. We’d love to be sailing today. But the warm weather is perfect for these kinds of jobs that involve goos that need to set correctly.

We’re also paying Zimmerman Marine to properly rebed our hatches.

Here’s view of the deck after the decorative wood-work was removed.

Top-left of the image is a hex-nut on the latch.

The corner has a bit of a gap.

There’s an aluminum rod from about top-center to top-right. That’s what holds the hatch open to let in air when it’s warm and sunny and you’re bobbing at anchor.

The gap is where our skills and abilities end. We’re hoping the boatyard folks can find any other voids in there and make sure they’re properly sealed up to eliminate water intrusion. I’m sure they have the experience to use the right goo.

It turns out that we have other leaks. We’re not sure, because it’s so hard to observe, but the hawsepipe behind the windlass may be leaking. We think it’s not bedded properly. We think we can do this ourselves.

It was cold — we fixed things

Two weeks ago, I broke the catch of Red Ranger’s bar.

Thus lead much swearing. And this clamp-and-webbing catch.

The clamp holds the webbing. The webbing holds the bar.

It’s a shabby necessity. A “jury rig."

There are two choices. Replace the “ball and socket catch” (or “stud and socket”) with a new one.

Or.

Find something else to hold it closed.

Enter the Perko cupboard bolt.

We put one on the bar.

And other on the cabinet aft of the bar which would also — sometimes — fail to remain closed in rough weather on starboard tack.

(When heeled over to port, stuff would sometimes pop out of the cabinet.)

Previously, we’d used a lot of different things to hold the cabinet shut. The best was a giant rubber-coated “gear tie.” Holds well, easy to undo. Ugly in the context of teak furniture.

These catches are really nice. But. Visible. This is “finish carpentry.” The Scariest Thing On A Boat.

Scariest.

Meanwhile, I talked CA into making a cover for the windlass.

A brutal undertaking because the thing is irregular in the extreme.

And.

There’s no easy way to hold it down.

The base had a few snaps, but they rusted away (mostly.) It’s not easily drilling into the teak base right at deck level.

We think (maybe) we can drill tiny holes and force the snaps in with a screwdriver. It’s awkward, and we’re not sure what’s best.

We do know that we don’t want anything near there to catch does or anchor lines or chain. The fittings need to be FLAT.

I did this, too, but this is easy. The software (mostly) upgrades itself.

A few devices need some hand-holding up upgrade. But. I think I’ve got a solid procedure.

Next weekend?

I broke the set screw holding the handle on. That means I can’t replace the mixing valve inside. The valve that I replaced ten years ago. The one that’s dripping. 10¢ set screw breaks and I have to but in an new $100 fixture.

I think it was a Delta Classic 100. The base is 10″×2″, which (I think) really limits what can go in there. I think there are a few Delta Classic and Foundations models that will fit in the narrow space available.

The newer models seem to require 2½″ for a one-hole installation. I don’t think there’s 2½″ between sink and backsplash. I’ll be studying the catalog and taking a lot of measurements. I really want the 100-DST. But. 2½″.

Home Handicrafts — Seizings

CA cleaned. And cleaned. And cleaned.

It rained much of the weekend.

I managed to drill out four screws and remove one of the mast steps to make it easier to put on a sensible sail cover. There’s more to report here in the long run. For now, let me say it was one hour per screw.

per screw.

Also. Cheap bits break. The titanium nitride (TiN) bits with a 135° tip rock. Even through a ½” of stainless steel. Eventually.

We use a snubber line on our chain. It runs from a bow cleat down to the chain, letting us ease the chain until it hangs loose and this rode takes the strain on cleat and chock instead of directly on the windlass.

We’ve been using this line for — well — since we started anchoring.

The big steel hook fits nicely over our ⅜” BBB chain. The eye is woven directly to the hook, with not shackle.

The rusty loop used to have a galvanized thimble inside it. The thimble rusted away because it was connected to a stainless shackle at the base of the bobstay, and constantly in contact with stainless steel and saltwater.

After the thimble failed, we moved it up onto the deck. It’s easier to monitor, since it’s not down under the water handling the chain. The picture doesn’t show this, but the line is smaller line than our ⅝” anchor rode. When it was time to replace, I looked for something bigger.

The two hand-woven splices (while messy) have held up well over the years. But. All the messy splices eventually come to an end.

This is the new snubber. The old hook now has a shackle so I don’t have to cut the line to get it off. And the loop at the other end is big enough for any cleat on the boat.

It’s ⅝″ line, to match the anchor rode. The loops are not spliced in, they’re seized. This is much simpler to do, and it appears that seizing can take a fair amount of strain before breaking.

Looking at the Findley’s Rope-Works collection of knots (page 17) has an illustration of a loop with three seizings to be sure it always holds.

I’ll add a second set of seizings, I think. They’re quick to do, and easy to inspect for wear. Findley suggests using “racked” turns closer to the eye. This leads to a “flat” seizing, distinct from the round seizings I’ve done already. Should be fun.

https://ropeworks.biz/reader/seizing.pdf

BTW. I like Findley’s approach slightly better than Brion Toss’ approach. Toss starts with an eye and wraps up and then back. Findley starts in the middle and both the initial turns and the riding turns work in the same direction. And with Findley’s method, I don’t have a weave a tiny eye into the twine.

The big win here is that woven splices are limited to three-strand line. A seizing, however, can be done in either twist or braided line. Rather than learn to splice double braid, I can put in multiple seizings. And replace them as soon as they look sketchy.

(Looking at the picture, I may add a thimble, also.)

The Thing from Below the Foredeck

We’re tortured by The Thing from below our foredeck.

Like a malevolent toad, squatting on deck, it stares at us in the cockpit.

In rare moments of lucidity, my partner’s gibbering includes claims it rose from the chain locker, smelling of charnel horrors, and cold as the forgotten tomb. Black as unending space, it hunkers on our foredeck, calculating, watching, waiting.

It has seen the blackest, foulest, mud-filled depths at the bottom of the sea. We’ve thrown it overboard, and hauled it, unbidden from the cold waters against its will, struggling and cursing it, but still, pulling it closer and closer.

It holds us — my partner and I — like a vise, clamped against a single point in the trackless oceans. We can no more escape its grasp that it can free itself from the Red Ranger, its overlord and cruel mistress. Can we free ourselves from it? Or are we bound to it forever?

Gazing in awestruck fear at this monstrosity, we wonder at its life. How was it created? What brought us together? Are there clues to breaking the links that bind us?

My partner replies in the affirmative: there are clues. They claim we can free ourselves from it. I was unconvinced.

The date I first beheld The Thing is etched on my brain like a scar that will never heal. The memory reawakens me from the deepest slumber. I bolt from the bed, running to check. To check what? My apartment is small, and land-locked, far from the sea.

The old man by the wharf where our boat was moored when we took ownership may not have been what he appeared. He looked, if not normal, at least conventional. Indeed, he wore a kind of smile that seemed distant from a rictus or a grimace. He told stories of boats and the sea with a practiced ease. We can’t label his words as deceptive when we were willing dupes, eager to see the world from the decks of a boat.

Did he mention the Thing? My partner says, “No.”

I’m not so sure.

I know a thing or two of the necronomic arts. A thing or two I should not know. A thing or two that should have been forbidden mortal men. But I come from a line of librarians: my mother, her mother before her, and so on. We have access to — let’s call them resources — that are not commonly available. These are not the kinds of books one finds in a tobacco-stained bookstore on the cobbled streets of Providence. There are not the kinds of books found by eager booksellers who have basements filled with shadows and books not available to the general public.

Passing sailors told us what to do. Whispered conversations away from prying eyes. A few quiet words in the darkness at the end of a pier, water lapping at the pilings. The smell of rot and filth all around us.

“Galvanize it,” were the words. “Galvanize it with acid, or die.” Sometimes a gesture to ward off evil. Sometimes a word in a foreign tongue. A tongue not bound to land or country.

And the sailor would move on, departing on another boat. Leaving us behind to wonder what we had done to ourselves.

You do see how it works, don’t you?

Each step is a choice. A choice we make. Evil and death are on both sides of the path. We take steps that totter helplessly between unknowable horrors. One false step and we are lost forever, wandering, hopeless until we come to a reckoning with the earth’s foundations, and wash up on the rocky shores, dead, or nearly so. Indeed, death is perhaps the better alternative.

My partner claims to have a plan. Some avenue that will free us from The Thing. I am not certain such an avenue can even exist.

In the early days, we were filled with optimism, high hopes, and bright hearts. We looked with magnanimity on the world. We tried to avoid talking about The Thing. We had clever euphemisms that aged like a dead squid, rotting and smelling until the words filled us with revulsion and fear. We tried to avoid talking about it, but for years — many, many years — our lives depended on The Thing.

I want to say “life is a maelstrom,” but this sounds too melodramatic. Let me, instead, say “life is punctuated by maelstroms.” We have hours of lassitude, boredom, ennui, punctuated by moments of pure horror. Those moments of terror are where we see the empty abyss opening before us. It is that very opening — the yawning depths of endless wandering in space — too vast to imagine — where The Thing prevents us from being consumed by the void.

Are we grateful? The Thing is beyond mere human sentimentalities like gratitude or grace or forbearance. Like a mountain of solid iron, the thing exists wether we are happy or despondent or tortured by nightmaric visions of what could have happened.

“There is a bitter end,” my partner reminds me.

“All endings are bitter,” I reply.

I cannot fathom the distances my partner is considering. They’re vast. Vast and dark, filled with the stench of death, and the cold at the bottom of the sea.

I have seen nights of fear and days of unending toil. I have looked across the trackless vastness of the sea. I have rocked in the menacing claws of the storm. My parter, too, has pulled me, insensate, from the deck of the boat, calling my name above the howl of the wind, thinking me dead.

“We can’t live with the Thing,” my partner declared.

I didn’t know what to make of this at first. We have come to depend on the Thing. Not in a positive way, not the way a plant depends on the light of the sun to grow. The Thing is a weighty, horrid presence. We don’t depend on it, but rather we tolerate it and come to expect it. With a horrid fascination, we anticipate its attendance, we treat it as an eidolon we cannot be rid of.

“We can’t live without the Thing,” I replied. My soul, filled with darkness, did not cry out for freedom. I did not see any light; the hulking darkness of the Thing had begun to blot out my vision of any world outside the cold, dark, death-filled depths in which The Thing seems to thrive.

“The Thing can live without us,” my partner replied.

I had not been prepared for this. It was like a torrent of autumnal rain: cold, unforgiving, piercing to one’s heart. The Thing could abandon us was a dark thought, rending my personal darkness with an inky black void of The Thing’s more profound darkness.

If The Thing leaves us, unprepared, the consequences are disaster. Nothing less. If, on the other hand, we have taken the necessary precursor steps, the disaster could be mitigated. This was my partner’s plan. There could be a life without The Thing lurking, watching, calculating.

We have formed a kind of pact between us. An uneasy truce. My partner will try to focus on things that truly are — tangible things — things visible to others. A retreat from the spiritual world. I will try to shed the darkness that envelops my every thought, and try to look to the light. Together, as partners, we can perhaps rid ourselves of The Thing.

I’ve been asking around. Few will speak to me in any useful way. Either they don’t know, or — like my partner — fear makes them incoherent. The hollow-eyed sailors, people who’ve seen to much, and endured for too long, also speak of the bitter end. It’s there. It takes a kind of patient malice of one’s own, a brooding, muttering, plodding kind of work to seek the bitter end without being consumed in it.

It takes foresight.

The knife must be ready at all times. The Thing is not part of us. It is associated with us, casually. We are ships passing: there is a hail, a brief exchange of signals, and we part. We must watch for the Thing’s foreshadowed ending. We must be vigilant and ready to strike the ties that bind us. Once we’re parted, the Thing must be shunted away, exiled.

We can separate ourselves from The Thing. But we cannot end the torture. This is the human condition: we suffer in fear of being cast adrift, of wandering. We seek permanence, a firm mooring, a foothold. These are not granted to us, but must be sought. The Thing offers a sense of place, but it is fleeting, and corrupt. The Thing cannot be trusted.

If out partnership is strong, we can free ourselves from The Thing from Below the Foredeck

Cambridge and the Autopilot

The West River Sailing Club cruising group ordinarily has a half-dozen cruises throughout the season. We were away, living in Nevada for some of the sailing season. With a pandemic, a cozy get-together is not a great idea. So, a cruise was a surprise.

Some folks from the club decided to have one, carefully distant get-together in Cambridge, MD. Their boat was being repaired. They needed to pick it up. May as well make an event out of it. It was a delight seeing folks after being away for a little over a year.

Red Ranger performed pretty well for out first big outing in about two years. Pretty well. Not perfect. Details to follow. What’s important is knowing what you don’t know.

As noted in the previous posts (back to July) we’ve been doing a lot of fix and repair and clean and refurbish. A lot.

This (nearly) perfect weekend had a few glitches. It also had gorgeous weather. And a moon a few days past full. The wind was too light (and from the wrong direction) for sailing. But that means a perfectly calm night at anchor in the Choptank.

Mr. Lehman. On Saturday morning, Mr. Lehman (almost) would not start.

I worry about the starter and the solenoid and the starter switch and the batteries. The starter, in particular, is a worrisome thing. It’s big, heavy (50 odd pounds) and right awkward to replace. It is (however) a commodity item that Ford has been making for years, and can be rebuilt by competent starter/alternator shop.

But. It was cold. Not below freezing level of cold, but cold enough that the engine cold-start (“Excess Fuel Device”) should have been used. I know this, but sometimes, I forget. It works like this:

- Move throttle control lever to max.

- Push the excess fuel button on the injector pump. It clicks in. It will pop out when the engine starts.

- Return throttle to ½.

Seems so simple. Did I do this? No. Should have.

Autopilot Pump. The Cetec Benmar pump (the only thing left from the old CourseSetter 21R Autopilot) didn’t work.

Total Panic. This is not an operational thing like the excess fuel device. This is Dead. Pump.

Dead.

I tried a bunch of things while we were under way. Nothing. It’s not like it's difficult to hand-steer to Cambridge. Six hours. Fun after having been in the desert for a year.

I didn’t install the autopilot system. There’s a lot I don’t know about the installation.

Scout. The big party. Which meant prepping and launch Scout. We had inflated her Friday at the dock, and she’s rock solid after living below decks for a year. The last set of patches are holding.

We’d bought a Dewalt inflator. It has a high-volume pump that runs off the same 20V batteries as our drill and saw. It does 90% of the air. Then. We top off with the hand pump to get the tubes to pressure. This works well.

Cooking Under Way. This isn’t easy. In rough conditions, below deck can be hard. At night, in rough conditions, it’s really hard. During the day, it helps to take the sun-shade off the window and gaze at the horizon while cooking.

CA made a pasta salad. Boiled pasta. Chopped veggies and cheese. Assembled our dinner bowls and put them in the fridge to wait for party time. I was impressed that we could have something so fancy. I hoovered mine without taking a picture.

Tohatsu-san. Mr. Tohatsu, sometimes known as Mr. Nissan, but his real family name is Tohatsu, worked flawlessly. It’s an 8 HP, two-stroke engine, and it started on the first pull.

The. First. Pull.

(I’d tested it at the dock, Friday. That was 20 or 30 pulls. And then. He ran. Perfectly. But Saturday night, on our way to a party?? Wham. First. Pull.)

On our previous boat, we had a tiny (1.75HP) two-stroke engine. It stopped working. I took the entire thing apart, found the bit of crud jammed into one of the valves, put it back together. And it worked. Tohatsu-san holds few terrors.

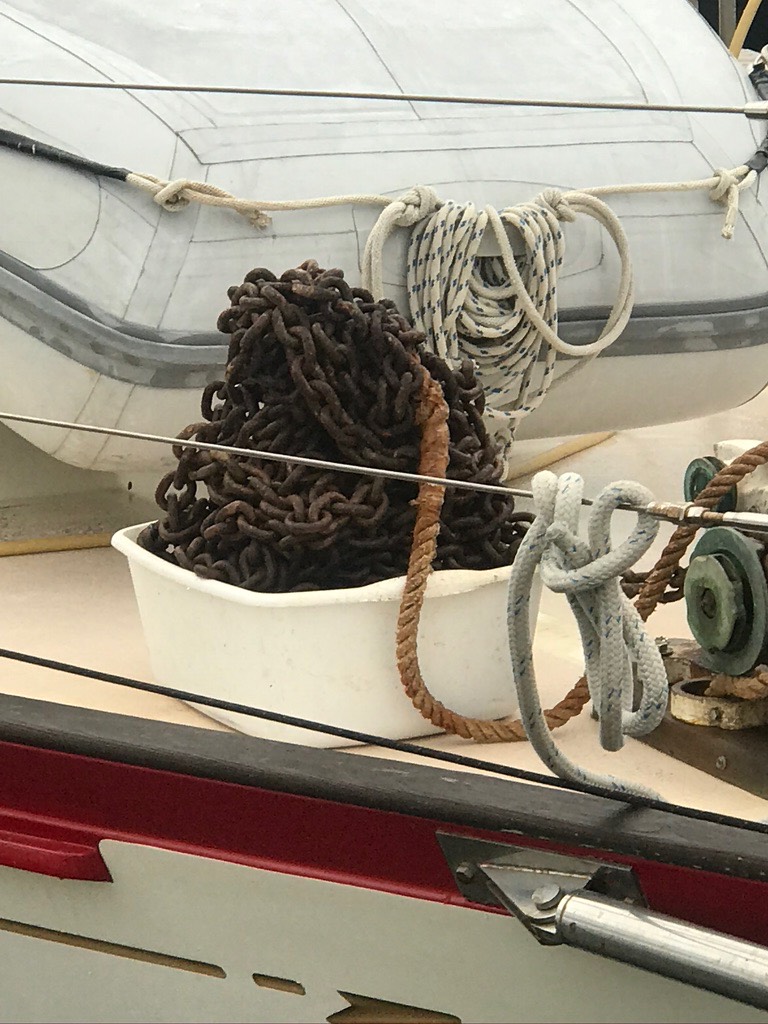

Anchor. Chain needs work. A thorough cleaning. Checking for links that are too thin.

The picture is looking down from the pulpit at snubber and chain.

Party. Delightful. The West Creek Yacht Club folks sat, masked, in a big circle and shouted at each other. It was fun. Distant, social, fun. Much hand washing afterwords. These are good people. Careful, prudent sailors.

Full Moon. Over the river. We’re a few days past full, so, the moon rose well after sunset.

Night Lights. Maybe four years ago, in an Ace hardware store, we say a box of green, rubber, solar-powered globes. They are Firefly Silicone solar lanterns. (https://seadogboatingsolutions.com/firefly-silicone-solar-lantern.html)

These Firefly lights can be charged from USB ports (which we have a lot of.) But. They can be placed under the window of the dodger to charge. Then you can hang them from the bow and stern to provide low-level marker lights for inattentive power boaters who don’t see the mast-head light.

They’re on-at-dusk, off-at-dawn, and you can set them out when you anchor and leave them there. I recommend using a tiny loop of string to let them hang below the level of the aft bulwarks. They will fill the aft cabin with light. All night. (Bring them in when you travel to avoid salt spray.)

The Luci inflatable lantern covers our cockpit needs nicely. It seems to charge readily and lasts easily as long as we need light in the cockpit at night.

Stove Igniter. Dead. We had replaced the “Spark Module” on the Force 10. That wasn’t it. We’re going to replace the button. We don’t really know what failed, and I worry about playing with it. The Spark Module turns 1.5V DC to 12,000 V at the burner. I’m a little cautious about doing diagnostics. It seems better to just replace things. Until the button arrives, it’s the flint striker. Works well. Can recommend everyone have one by their propane stove. Better than matches.

The Bar. I broke the catch on the bar door. It’s an old Perko 0559 catch. We need to replace several. I like the Perko Cupboard Bolt. It’s surface mount without too much fuss. I think the other cabinets with the original catches should be upgraded to bolts. CA found some on eBay.

Here’s a picture of a clamp with line tying the bar closed. Sad.

Autopilot Pump. Sunday morning. Plenty of hot coffee. Good night’s sleep. Beautiful, clear day. I looked the pump over carefully. Not a drop of missing hydraulic fluid (pressure is high, manual steering works.) Wires are solid. Fuse is good.

Flip through the “Commissioning” pages on the Simrad AP-44 display. Eventually, I would up at the “Rudder Test” option in the Autopilot control panel. This did nothing. Zero. Zilch. Zip point Doo Doo.

Test. Failed. Tried it several times to be sure. Failure.

Bad. I think the pump is dead. But shows no signs of death. Physically, it looks good. CA disputes calling it dead when it doesn’t have a sign of failure.

And. Worse. I didn’t install this. I paid folks to install it. That ramps up the “I don’t know what I don’t know” factor. What don’t I know about this? While CA doesn’t dispute this, she has some weird confidence I should be able to “somehow” diagnose the problem.

Much Worse. It’s almost inaccessible. It’s behind the muffler (the big black hoses to the left) in the inaccessible corner of the engine room. To even reach it requires climbing over the engine. Looking closely at it? Nope.

CA pointed out that I upgraded a lot of software. Perhaps some configuration parameter was not correctly saved and restored. Or maybe they added a feature which is now misconfigured.

“Bah,” I replied. Foolishly.

After we got back to Herrington, I looked at the configuration parameters (again.) See the ftp://software.simrad-yachting.com/autopilots/NAC-2_NAC-3_CM_EN_988-11233-002_w.pdf commissioning manual for the number of features that need to be setup correctly.

Eventually, I noticed “clutch”. It was enabled. As if there’s a clutch control somewhere. (There isn’t.) (Apparently, there’s an “engage” wire in the controller to trigger a clutch. But. We don’t need it.)

Change the software settings from “clutch” to “auto”. And the self-test seems to work. It worked twice at the dock. So. I think we’re back in business.

Without an expensive new pump. And without a super-expensive service call to have experts look it over.

I’m going to track down the paper copy of my commissioning manual, and write down *all* the settings to be *sure* I’ve got a grip on this.