Travel 2017-2018

Counter Top Replacement

The whole story is kind of complex. The bottom line is that we have a counter-top issue in Red Ranger’s galley. A serious “Concern”. Or maybe Concern in bold.

There are two strategies available. (Three, if “Ignore It” is a strategy.)

- Replace the counter top with a new counter top using new materials.

- Skin the counter top with something that conceals the “concern.”

When we lived in Florida, we put a layer of composite particle board on the counter-top. It was super-easy to work with, because it was flexible. You could cut it and force-fit it into place. A little silicone and we were done in a day. Done.

It was nice. For a year or two.

Now it’s looking a little icky. And we (by “we”, I mean “The Commodore”) saw kitchen countertops made from recycled materials.

“Ooooh,” was the command I was given.

Start here: https://www.greenbuildingsupply.com/All-Products/Cabinets-Countertops-Countertops

Wow. The Richlite recycled paper. Wow. Wow.

But.

That requires dismantling the galley. The fiddles have to go. And then I have to figure out how to replace them. The countertop includes a cupboard with a lid in it. I’d have to figure out how to cut the countertop to put the hinged lid (with a nice frame) inside it.

That’s serious finish carpentry. Careful cutting. Proper tools. Several days to get it apart cleanly. A week or more to reassemble.

Nope. Replacing the counter-top is a big-old nope.

And. The smallest piece of Richlite is immense. Fine for your terrestrial house. But way too big for the 36″×18″ space.

The Skin Alternative

Here’s what we did instead.

https://www.mscdirect.com/product/details/52421575

This is High Density Polyethylene (HDPE). It’s a cutting board. NSF-safe cutting board material. Suitable for food handling. It’s ¼″ thick.

It sits on top of the old material nicely. It’s awkward to cut because it’s super flexible. You really need an assistant (or a table saw) to keep it from flopping around why you cut.

It sands (and files) like wood, leaving a million little plastic beads. Have a vacuum cleaner handy.

It doesn’t drill well at all. It catches the bit in a curlicue of plastic and the drill jams and wrenches.

The big holes have to be cut in phases. Cut for a few seconds. Pull the hole saw out and knock out the plastic that accumulates in the teeth. Cut for a few seconds. Knock out the plastic. Eventually, you get all the holes cut. Maybe your hole saws are better than mine, but mine jammed solid.

Cutting the sink hole isn’t too bad. The wood isn’t exactly the right shape so, I cut inside the wood and then filed and sanded until the sink went in. The clamps hold the sink against the underlying wood, so it’s solid. Solid.

However.

The fittings (two fresh-water, one raw water) are now going through a countertop that's ¼″ thicker than it was before. It appears that most fittings expect 1½″ and that’s how long the threads are.

In particular, the back of the Delta faucet had two big plastic “nut-with-washer” things that hold the faucet assembly down. The bold was now too short, only a few threads would grab. But. A ⁹⁄₁₆″ nut with a big fender washer seems to do the trick.

Edging

So. There’s this edge around the HDPE skin over the counter top. What to do?

Nothing adheres well to HDPE. Silicone sealant will cling, but it’s not a proper adhesive. Clear silicone it is.

And. This thing I learned online.

- Vinyl Glove.

- Rubbing Alcohol.

- Two Paper Towels.

Silicone the seam. Remember. Push the bead forward from your caulk gun.

Done?

Splash some alcohol on one paper towel. Put on your gloves. Wipe your finger with alcohol. Run it along the silicone bead to push it down and create a nicely curved fillet.

Wipe the excess silicone onto the dry towel. Refresh the alcohol with the wet towel. When you’re done, it looks really good.

Back Story

In case you’ve gotten this far. The story is long because the Whitby was designed with a double sink. In the confined space, a 24″ double sink means two sinks that are too small for anything useful.

The previous owner had replaced it with a single sink that was 20″ or so. And a block of wood to fill the void. The wood rotted.

We put a particle board skin down. It was ¹ ⁄₈″ thick and didn’t matter much when reassembling the fixtures. Now we’ve got something that will last the life of the boat.

The Portlight Issue

The Whitby has a dozen opening portlights. Plus three hatches.

In the bright, tropical sun, it can get warm. Really warm.

The previous owner had curtains. We took those out because they’re dust and mildew catchers.

We tried to make window shades from HDPE board. If you’re careful, you can cut a piece of “ Laminated Polyethylene (HDPE) Corrugated sheet” that fits the lens of the Beckson Portlight, and wedge it in. It cuts most of the light.

Yes, they get old and brittle. But they’re cheap! $12 fills all of the portlights with a shade.

We’ve decided to try some SOLYX window tint film. CA got some samples. They have patterned privacy films and different levels of transmission for UV protection.

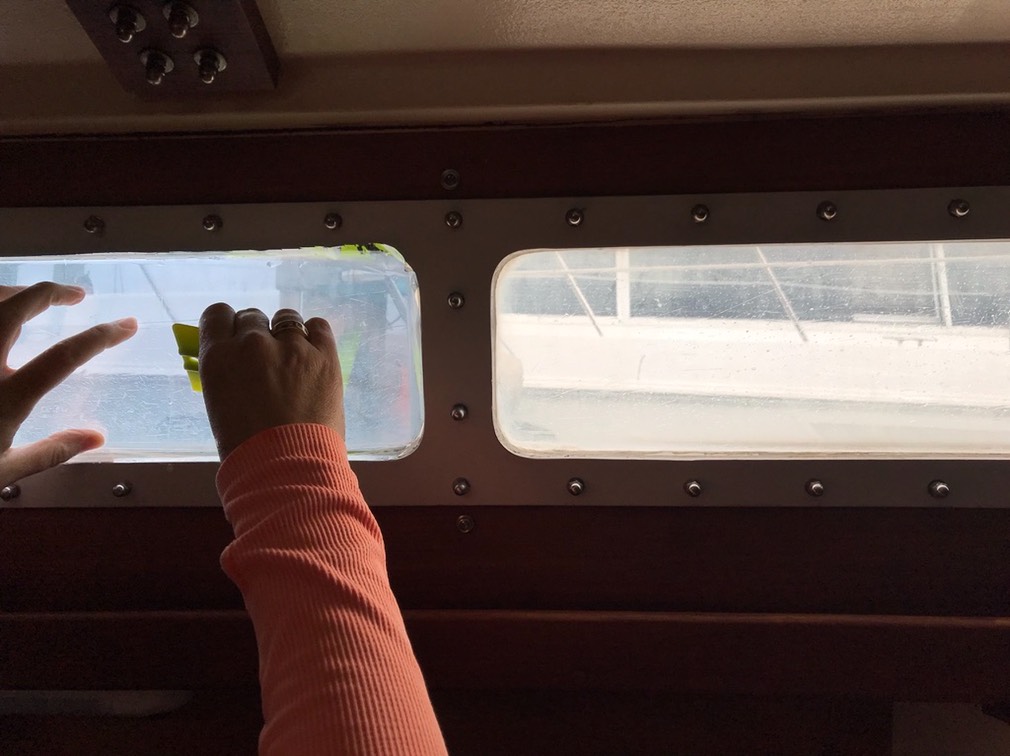

Unretouched image of film and no-film.

She also bought SOLYX’s little installation kit with the fancy squeegee and box-cutter. We had a squirt bottle to mix up soapy water — this is essential.

Also, they talked about using two pieces of tape to separate film from backing. There’s a knack to this. Once you figure it out, you can use two pieces of masking tape and — with only a few false starts — get the plastic to separate. While you’re peeling, squirt it with soapy water until it’s so slick it will slide all over the window. She squished it on, and then carefully used the razor knife to trim the edges.

It’s exacting work. Stressful because the material is so fine, it’s hard to make a clean cut that doesn’t involve tearing some part of the file.

We had to take a stress break to make espresso after doing the six portlights in the main saloon and v-berth.

We waited until the next day to do the aft cabin. Once that was done, we could mess with hose clamps and other ordinary chores.

We think we want to add some more LED light bars. About eight years ago, I bought a really nice “Tigress” red/white LED strip. Back then, it was the state of the art. They’re not made anymore because simplistic red/white has become kind of dumb.

LED light bars nowadays are either bright one-color, or they’re RGBW with a color-mixing control that allows you to pick any color you want. Or let it do different sequences of fancy color displays. The shopping is excruciatingly complex.

We also want to replace the counter-top. Something like Green Building Supply’s Recycled Paper Countertops looked really cool. But they’re thick and heavy and expensive. We only need a tiny (36″×18″) piece. This is difficult to buy, because the pieces tend to be huge. They don’t seem to offer a cutting service.

Instead. We’ll go with a big sheet of HDPE. Essentially, a cutting board. A little silicone goo to keep water out, and we may have a better countertop. Boring white, but without a seam and a leak.

Contrasts

It was a weekend of contrasts. Two dear friends came down to visit for the weekend and sail. We’ve had some drive-by visits where a quick sail on Red Ranger can be worked out. This visit was a stark contrast to those. These were folks looking to sail.

To make things more complex, we have tenants on Red Ranger.

Chris was seriously entertaining a “crack-of-dawn” departure: nautical twilight. 40 minutes before sunrise. Amy was not delighted with the idea because we didn’t need to cover a lot of miles by sailing through all of the available daylight hours.

Saturday, we got a comfortably early start. The wind built from what we call 10g15 (10 kn gusting to 15 kn, or F4) to a steady 17 kn (or F5.) When we cross over to Beaufort F5, conditions start to get sporty. The good news is that the sea state in the Bay was pretty flat, so it didn’t turn into Red Ranger crashing into the waves, throwing spray everywhere.

We started the day with a relatively simple Yankee-Mainsheet until the wind was clearly past the 17kn threshold. While we could reef the main, I prefer to drop the main entirely, and raise the mizzen. Since the winds were building and projected to keep building, jib-and-jigger seemed more prudent.

Our tenants — the crew of Island Time — were working at the United States Sailboat Show in Annapolis. That meant we could sail around with their apartment during the day on Saturday. Chris, Amy, CA, and I went back to DC to leave Red Ranger for the tenants on Saturday night.

On Sunday, we returned to the boat. The six of us spent a long time chatting while we waited to see if the rain was really gone or whether there might be a tiny bit wind.

The wind didn’t show up, but we went out for an hour or so and drifted around haphazardly. We rigged the mizzen stays’l to see if we could coax a little speed out of Red Ranger in the nearly still air.

On the left side of the picture is the mizzen mast and mizzen sail. There’s a red sail cover in the lower left corner. The mizzen stays’l is a vast contraption, stretching from just abaft of the main mast all the way back to the end of the mizzen boom.

Saturday — blustery and lively, Sunday — chatty and slow: a weekend of contrasts.

Whitby-Brewer Rendezvous 2017

When we bought Red Ranger, we bought more than a boat. We bought a family. This year’s rendezvous involved six boats at the West River Sailing Club dock, and almost 30 people in the various presentations.

CA put together an epic program and party.

Our trip up on Sunday was bouncy and unpleasant. There was 10 kn of wind directly on the nose. There was no alternative to bouncing up the bay. We hoisted the sail near the West River Green “1”, but only sailed for a half-hour or so. We had a schedule, and beating back and forth wasn’t really part of it.

While Monday is the expected arrival day, Sunday had good conditions and several boats arrived early. Our contract with WRSC doesn’t really start until Monday, but, the club was flexible.

The proper content begins on Tuesday.

We learned about the refit on Uhane Kai. It’s almost done. She may be departing the Chesapeake next year.

We learned about surveying from a local surveyor, Karen Alt.

We discussed weather, and weather resources. Terry, of Island Time, moderated the discussion. Here’s what I jotted down.

Attainable adventure cruising. https://www.morganscloud.com/about/

Modern Marine weather. https://www.amazon.com/Modern-Marine-Weather-Traditions-Technology-ebook/dp/B00BZDR2XE

http://Saildocs.com

http://passageweather.com

http://www.buoyweather.com

Delorme in reach weather

Weather underground marine

http://www.marvsweather.com/cu_01.html

We learned about the San Blas islands from the crew of Memory. Get Eric Bauhaus’ book.

We learned about dinghy renovation from the crew of Shooting Star. We’re going to buy some ToobSeal for the pinhole leak in our dinghy.

We learned about sewing projects from the crews of Indefatigable and Alembic.

We got some promotional gear from Sailrite, including hats, shirts, and tote-bags. We had a raffle to share the bounty among all the crews in attendance. (I got a new hat.)

And that was just the first day!

On Wednesday, we shared tips and best practices. This is facilitated by Deb, of Island Time, who makes sure that everyone can share their lessons learned with the rest of the Whitby-Brewer family.

The crew of Alembic talked about Western Caribbean destinations. Looking at the hurricane devastation in the Eastern Caribbean made this particularly poignant.

We also reviewed some more mundane details. Scott (of Joie de Vivre) showed is the latest features of the web site, including the Slide Show of boats. We looked at sales information about our boats. And we also have a brief “business” meeting. There’s rarely much business beyond reviewing our tiny budget and getting volunteers lined up for next year.

Indeed, the biggest budget issue is the pennant. We have been selling some appliquéd nylon pennants, and it’s time to reorder. The current material doesn’t stand up well in a marine environment. Maybe we should switch to printed dacron? Or appliquéd dacron? Or Sunbrella? Lots of discussion.

Thursday, we bid tearful farewells.

The trip back had (again) wind almost directly on the nose. The sea state was much flatter than the trip up. With a little care, we could keep 45° off the wind. With a wind-speed of 4 kt, we couldn’t really make much headway. We motor-sailed under main alone. This let us make a good speed (generally over 6 kn) with the engine a hair above idle speed. I think we set a record for the trip, doing the entire thing in 3h 20m.

The crew of Island Time are working at the Annapolis Sailboat show. Their boat is in Florida, so we invited them to stay on Red Ranger while they’re working up here.